Automation for powder chemicals DAP

The master of powders

DAP is engineered to dissolve powder chemicals up to a 1:1 concentration ratio. This enables a mere liter of water to effectively disperse a kilogram of powder chemicals, like common salt, glauber’s salt, soda ash, and others.

Alternative dissolvers

DAP offers a variety of dissolver tanks in different sizes, including 360 liters, 500 liters, and a specialized high-speed 500-liter tank for bulk consumption.

Many variety of silo capacity

DAP can be paired with silos ranging from 450 liters to 31,000 liters, based on consumption. These fiber-glass silos come equipped with level sensors and vibration units.

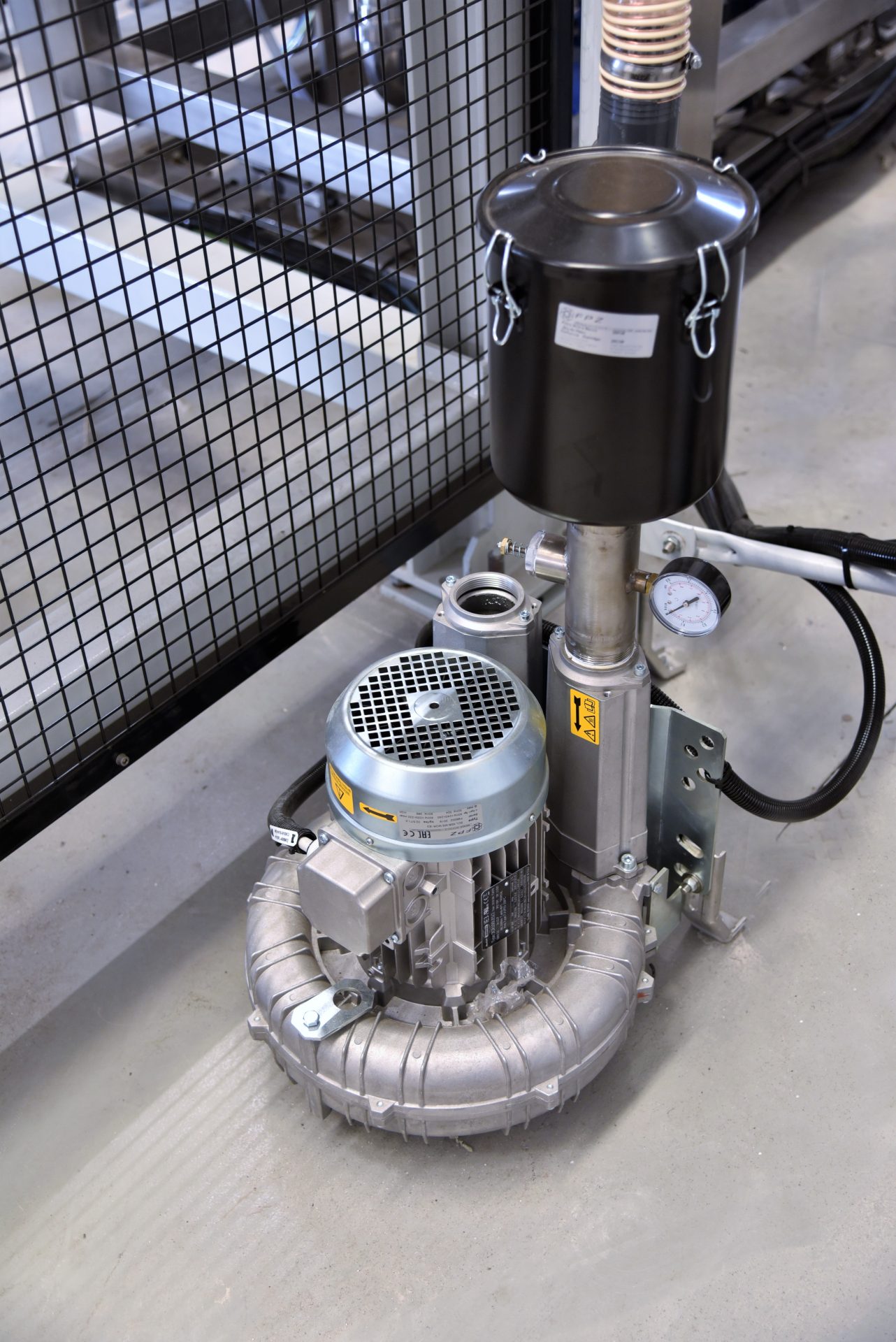

VACUUM LOADING

Powder loading is achieved using a vacuum system. The operator simply empties the bags into the hopper and the vacuum then transfers the material into the silo. With the aid of independent filter units for each silo, contamination-free loading is achieved.

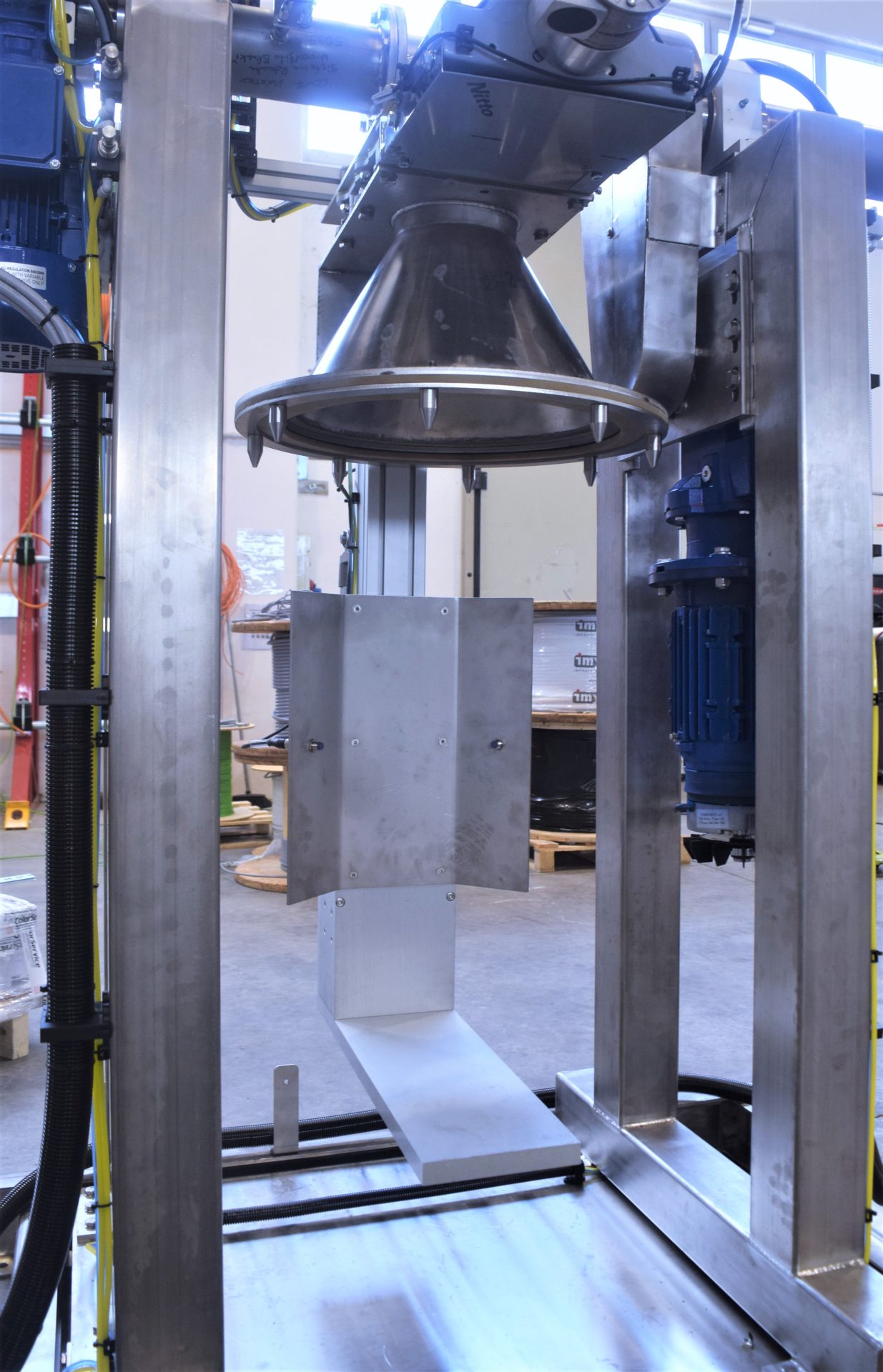

Big Bag

The DAP big bag applicator provides a convenient solution for attaching powders sold in large bags. Loading and unloading of these bags can be easily accomplished with a crane or forklift.

Special care for Hydrosulphite

Handling hydrosulphite can be challenging, but a specialized version of DAP can manage it. The silo used for handling it is equipped with a temperature sensor and a guillotine-type separation valve, which can be used to cut off the silo from water. After completing the task, the silo moves back for safety purposes. Additionally, an automatic unit blows nitrogen to prevent any possible fires.

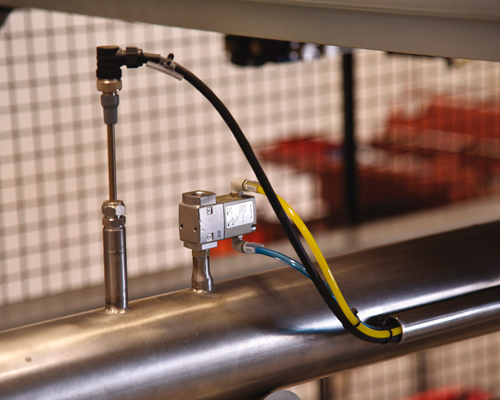

Mono or Multi line

DAP is able to work with mono-line and multi-line dispensing technology. Every dissolver can be connected to any of Color Service distributor family or 3-Way valves to deliver liquids. All dissolvers are flexible to work for both mono-line and multi-line technologies.

Hydrosulphite in drum

When hydrosulphite comes in drum from supplier, automatic drum unloading unit seals the drum and rotates. Content of drum can be used till last gram with isolation of air to keep hydrosulphite always fresh.